Improve supply reliability with the Supplier Disruption Report

Suppliers may fail to replenish orders, causing stock-outs. But how can we identify which suppliers are underperforming? Traditionally, companies have focused on On-Time Delivery (OTD). However, in today's uncertain conditions, it is crucial to have suppliers who are responsive to your needs and can adapt quickly.

The supplier disruption report can help you to identify which suppliers were not responsive enough and caused you to have a hard time maintaining your service levels.

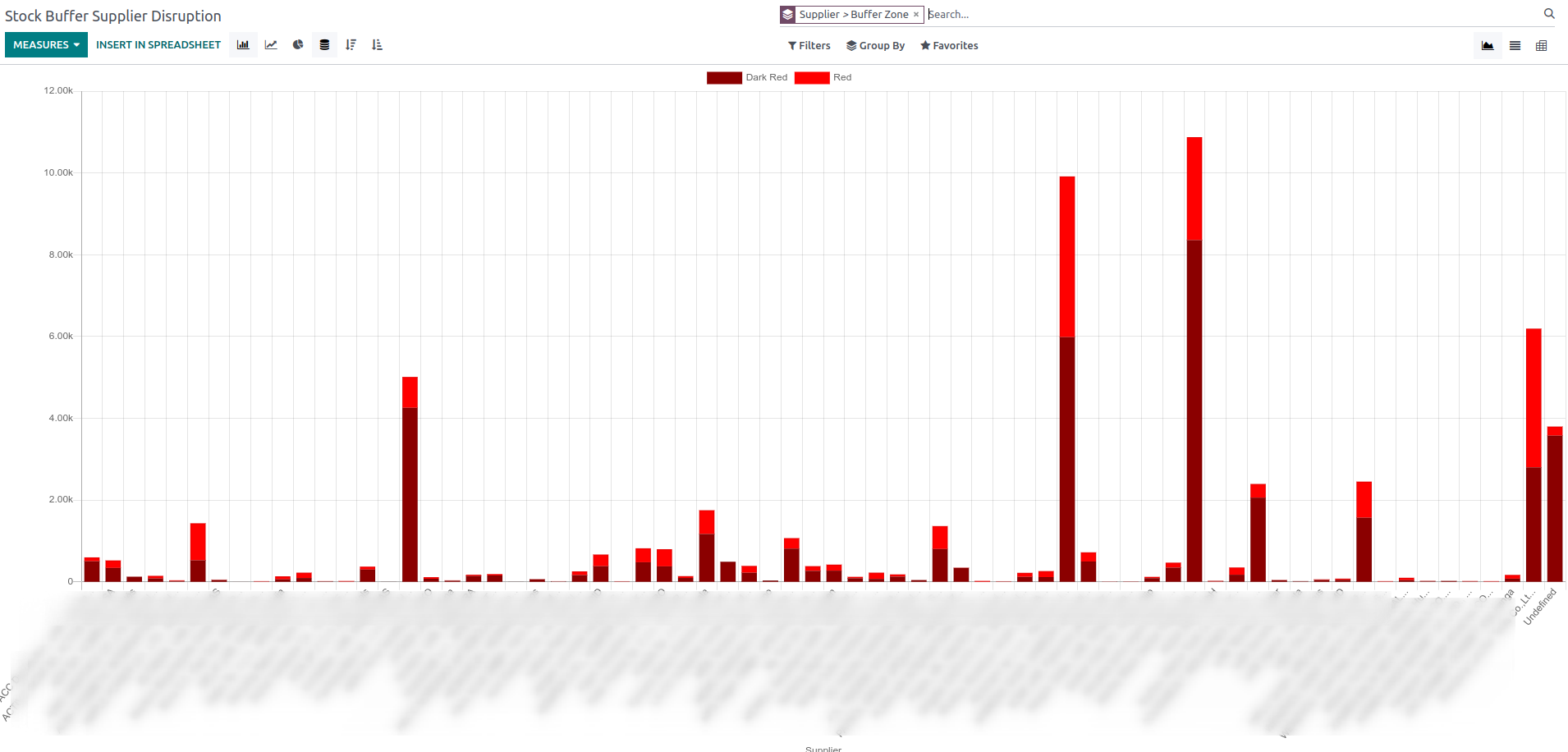

Supplier Disruption Report

This report shows the number of days where stock levels have been critically low or in stock-out, grouped by supplier.

For example, suppose a supplier that ships you two products, "A" and "B". You are analyzing the supplier disruptions during the last year.

Product "A" has been out of stock during 10 days, and "B" stock has been running critically low for 10 days and has run out of stock for 15 days.

The report would show 25 days in dark red (out of stock) and 10 days in red (stock critically low) for that supplier.

In the image below you can see, in the horizontal axis, each one of our suppliers, and on the vertical axis the total number days with critically low stock (dark red) or in stock out (red). Clicking on each of the bars will take you to the product inventories corresponding to the supplier.

Watch the report in action

Explore our related articles

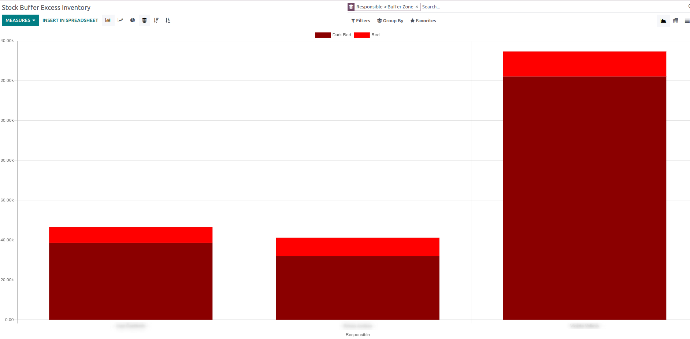

Evaluate stock managers reliability with the Excess Inventory Report

Use this report to evaluate the effectiveness in stock excess control. It analyzes the cost of excess inventory held, enabling comparisons with past periods to understand the evolution of the performance. This allows for a comprehensive understanding of inventory management efficiency.

Discover

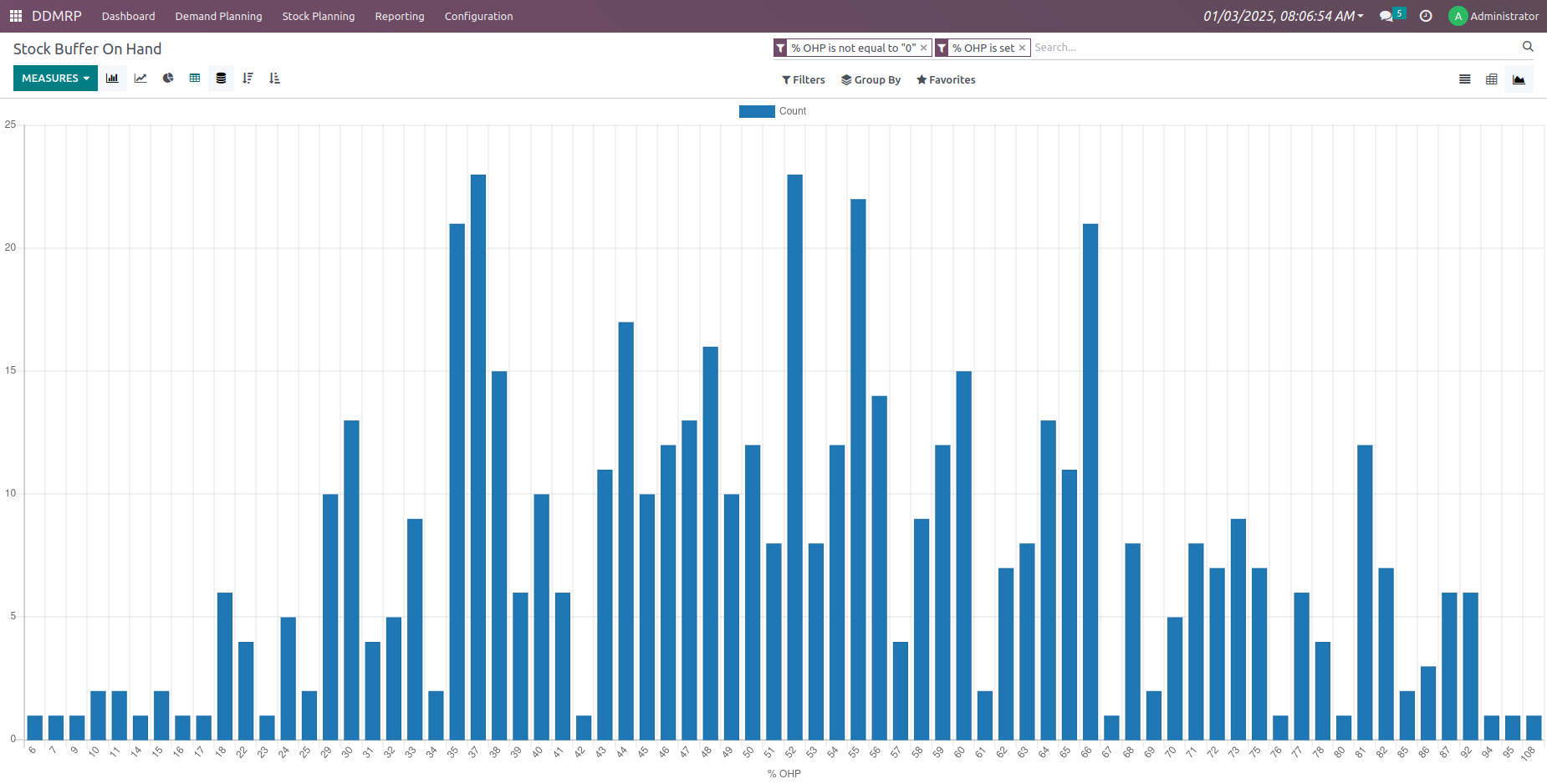

Assess inventory levels with the On-hand Distribution Report

This report shows the state of the inventories when compared to their respective optimal stock limit. This helps evaluate for which specific parts the company tends to hold too much stock and the overall inventory behavior of the company.

Discover

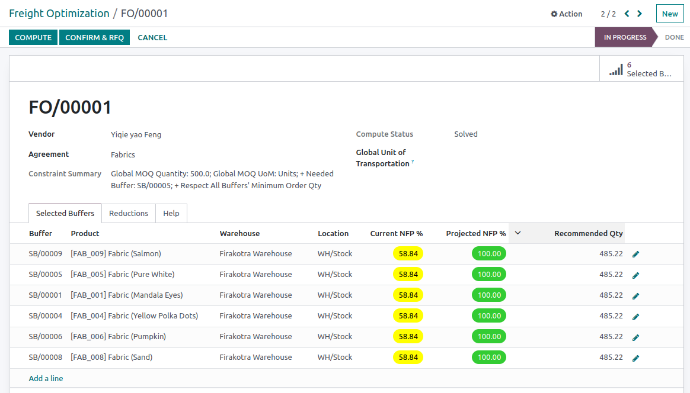

Ensure optimal replenishment orders with Freight Optimization

Replenishment orders are needed to maintain optimal inventory levels, but they are often constrained by different requirements the vendors impose on the order characteristics, like minimum order quantities or order price thresholds. This tool optimizes order quantities to meet the established constraints while minimizing excess inventory and associated carrying costs.

DiscoverIf you are willing to learn more, register to our 1-hour DDMRP Basic Training webinars. Send us a message and our team will contact you with the available sessions: