Protecting service levels with forecasts

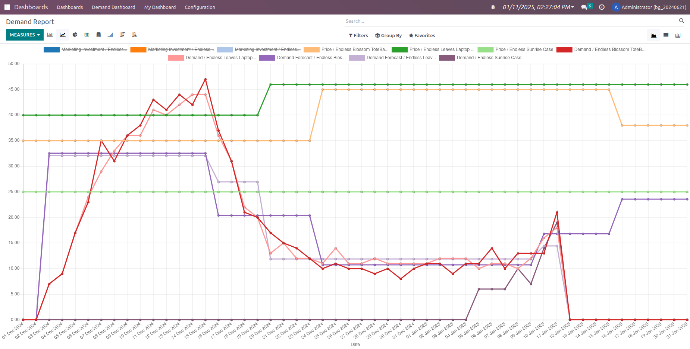

Forecasts provide essential data for operating in today’s volatile environments by offering valuable insights into future events. However, in a VUCA world, contingencies will inevitably alter our predictions. The question is not if disruptions will occur, but when they will happen. Companies must be prepared for these challenges and use their tools accordingly.

Bad practices

However, the effectiveness of this planning approach is threatened by one factor: variability. This method intrinsically hinders the ability to adapt to demand and supply fluctuations that can, and eventually will, occur.

How to use forecasts wisely

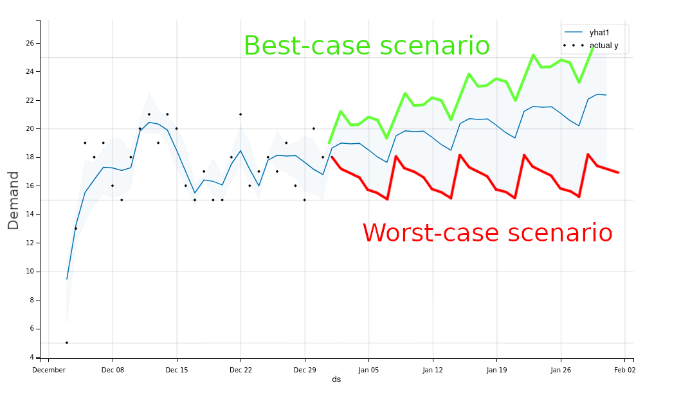

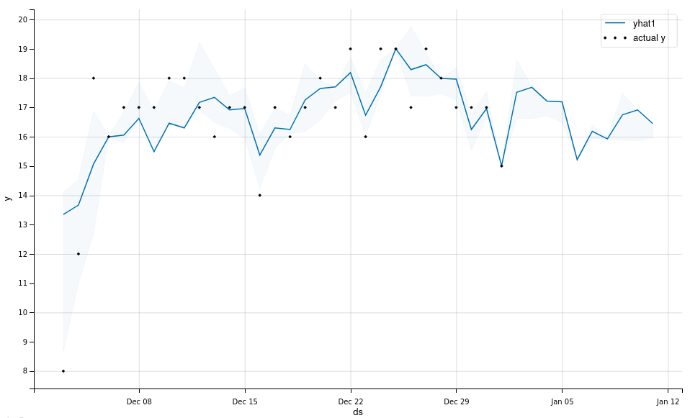

The implementation of forecasts cannot be approached in the same manner, as they also face variability and its accuracy can be impacted by unforeseen events. Therefore, companies must be prepared for these scenarios. Instead of generating replenishment orders exactly to cover for the most probable forecasted demand number, it is a better practice to consider the range of possibilities forecasts provide - what is called "confidence interval" in statistics.

The lower limit indicates the worst-case scenario, implying that with all available data, real demand is not expected to fall below this amount.

Conversely, the upper limit represents the best-case scenario, indicating that the forecasting model does not anticipate demand exceeding these values.

Explore our related articles

Introduction to Forecasting

Accurate forecasting helps maintain optimal inventory levels, reduces costs, improves customer satisfaction, and aids in strategic planning. Learn about its foundations and the possibilities it offers.

Discover

Forecasting with Regressors

Incorporating regressors into forecasting models is key to the improvement of the forecasts results since they allow to consider a range of external factors that influence demand. Learn how to boost your predictions with them.