Introduction to Forecasting

The importance of forecasting

Inventory management

Accurate demand forecasts enable businesses to maintain optimal inventory levels, minimizing both overstock and stock-outs.

Cost efficiency

By aligning production and procurement with expected demand, companies can reduce waste and improve cost efficiency.

Customer satisfaction

Meeting customer demand promptly leads to higher customer satisfaction and loyalty.

Resource allocation

Proper forecasting helps in allocating resources effectively, ensuring that the right amount of resources are available when needed.

Strategic planning

Long-term forecasts aid in strategic planning, helping businesses set goals and make informed decisions about expansion, investment, and market positioning.

There are several methods used for forecasting, each with its strengths and weaknesses. They can generally be separated into two groups:

Qualitative methods

They are based on the judgment and opinions of experts. Common techniques include market research, the Delphi method, and expert panels.

Qualitative methods are valuable for understanding the broader market environment, identifying structural changes, and capturing insights that are not evident in numerical data.

However, judgmental forecasting is particularly vulnerable to various types of judgmental bias. These include cognitive biases as well as intentional biases arising from misaligned goals and incentives across different areas of the organization. For this reason, qualitative approaches are often used as a complement to quantitative methods within structured decision-making processes, with the aim of mitigating bias and improving forecast quality.

Quantitative methods

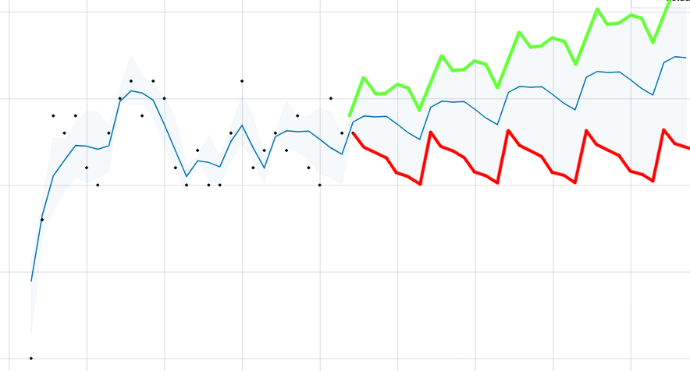

They use historical data combined with advanced statistical models, machine learning techniques, and artificial intelligence algorithms to predict future demand. These techniques include time series analysis, causal models, trend projection, and predictive models based on machine learning.

Quantitative methods are highly accurate and can handle large datasets, making them well suited to capture the complexities of market behavior and provide specific, actionable insights. This makes them particularly effective in complex and volatile markets, where accurate demand forecasting is critical for decision-making and strategic planning.

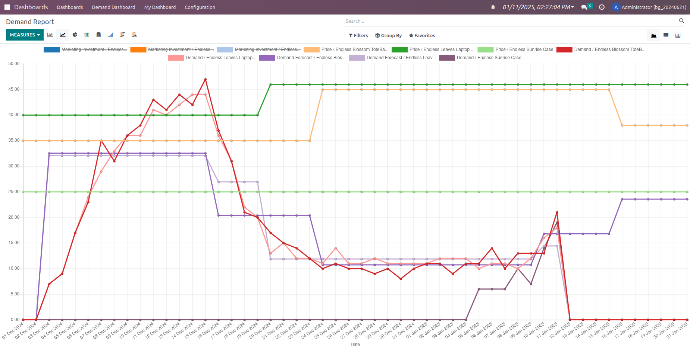

Transitioning to a demand driven approach requires businesses to balance the use of real-time demand data with accurate forecasts. Real-time data enables agile and responsive operations, while forecasting remains essential for strategic planning and ensuring the supply chain is prepared for future demand.

Explore our related articles

Forecasting with regressors

Incorporating regressors into forecasting

models is key to the improvement of the forecasts results since they

allow to consider a range of external factors that influence demand.

Learn how to boost your predictions with them.

Protecting service levels with forecasts

Forecasts provide essential data for operating in today’s volatile

environments by offering valuable insights into future events. Discover how to effectively protect your service levels with them.

If you are willing to learn more, please register to our 1-hour DDMRP Basic Training webinars.

Send us a message and our team will contact you with the available sessions: