In an era defined by unpredictability and rapid change, relying on rigid, forecast-driven planning is no longer sufficient. This is where Demand-Driven MRP (DDMRP) proves its value. Instead of waiting for disruptions or basing decisions on uncertain projections, DDMRP enables businesses to respond dynamically to actual demand by placing strategically positioned inventory buffers and using clear visual signals to maintain a steady and reliable flow of materials.

Follow along with this introductory guide to understand the principles of DDMRP and how it can transform the way your supply chain operates.

1. Historical Context: From MRP to VUCA Environment

More than 5 decades ago, Joe Orlicky introduced Material Requirements Planning (MRP), a true revolution in inventory management:

- Multi-stage planning through BOM explosion.

- Synchronization of components according to demand.

- Inventory reduction and improved prioritization.

MRP quickly became the standard for manufacturing companies. However, over time, the industrial environment changed radically (VUCA – Volatile, Uncertain, Complex, Ambiguous):

- Shorter customer tolerance times.

- Longer and fragmented supply chains.

- Products with shorter lifecycles.

- Forecasting becoming more difficult and less reliable.

As a result, many companies faced several problems:

- Many users did not fully trust the system.

- A large number of companies used spreadsheets to correct or replace MRP calculations.

2. Today’s Inventory Management Problem

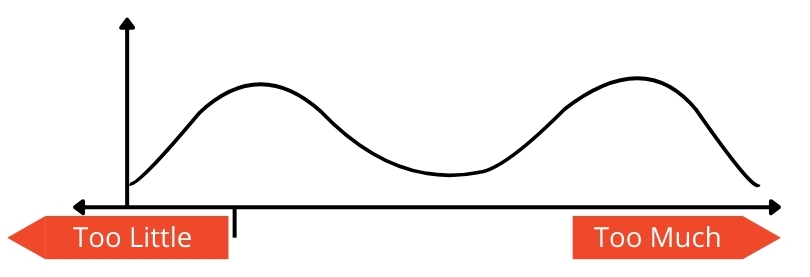

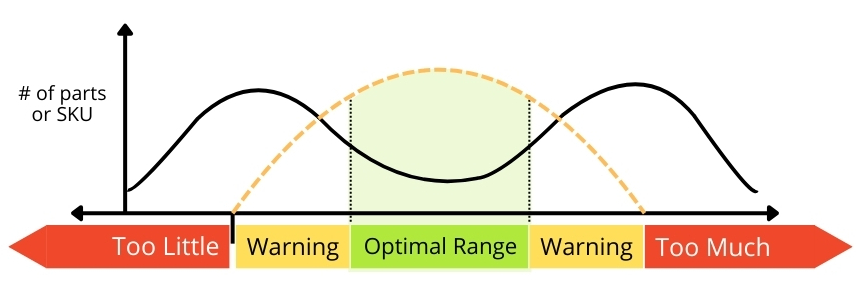

Most companies live between two extremes:

- Too little inventory → shortages, lost sales, interruptions.

- Too much inventory → excessive costs, wasted space.

Figure: Bimodal distribution — inventory levels oscillate between shortages and excess, with few periods of optimal balance.

This imbalance creates a bimodal distribution: very few items in the optimal range.

Figure: Bimodal distribution — inventory levels oscillate between shortages and excess, with few periods of optimal balance.

On top of that, each MRP run generates oscillations:

- Chronic shortages.

- Excess inventory.

- High expediting costs and waste.

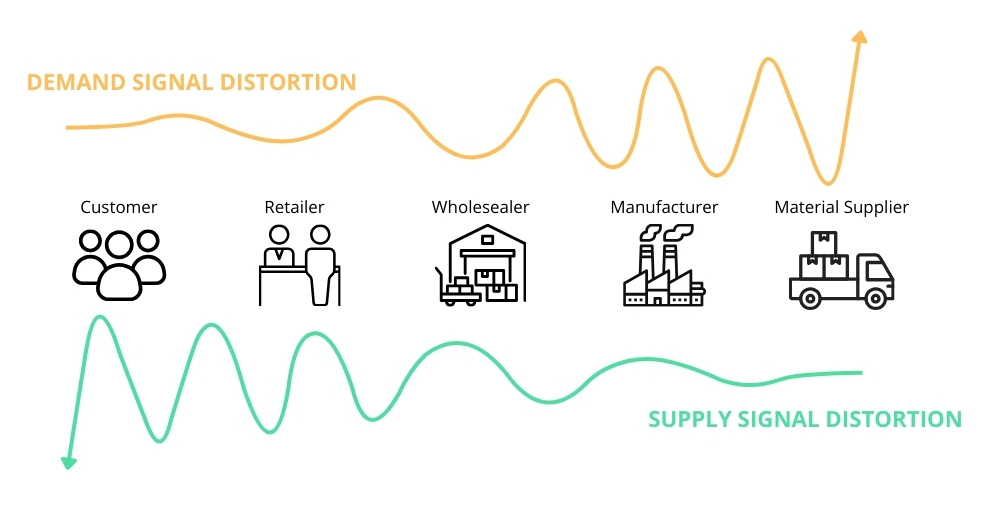

When these effects multiply across the supply chain, the bullwhip effect appears: amplification of variability in both supply and demand.

Figure: The Bullwhip Effect — demand and supply fluctuations amplify as they move through the supply chain in both directions.

3. The Solution: Demand Driven MRP

Demand Driven MRP (DDMRP) is a methodology for designing, planning, and managing supply chains with the main goal of protecting and promoting the flow of essential materials and information.

It is based on three key actions:

- Position: strategically place stock buffers.

- Protect: establish safety levels to absorb variability.

- Pull: generate supply based on actual demand.

4. The 5 Sequential Components of DDMRP

To put DDMRP into action, companies follow a clear sequence of five interconnected components. Each one builds on the previous step, creating a practical roadmap to design, protect, and manage a supply chain that truly responds to real market conditions.

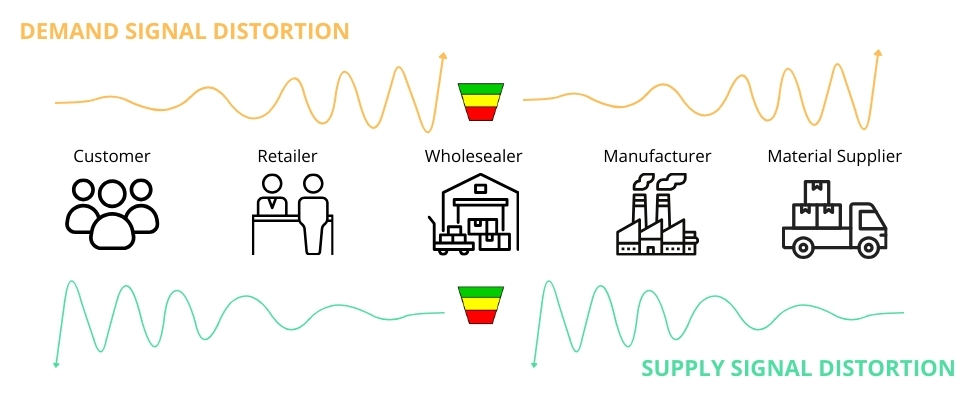

1. Strategic Decoupling (Position)

Place strategic decoupling points within the product structure or supply chain to:

- Stop the transmission and amplification of variability in both directions.

- Reduce the planning horizon.

- Shorten lead times.

Figure: Stock buffers and Bullwhip Effect — three-color inventory zones absorb demand and supply swings, preventing bullwhip disruptions.

2. Buffer Profiles & Levels (Protect)

Create inventory buffers at these points with 3 color-coded zones, each with a specific purpose.

- Based on historical usage and/or forecasts, combined with item configuration.

- Unlike MRP’s safety stock, which is static and often counterproductive, buffers absorb variability without generating false demand signals.

3. Dynamic Buffer Adjustments (Protect)

Adjust buffers up or down based on:

- Changes in actual consumption.

- Anticipated events or seasonality.

In classic MRP, reorder points and safety stocks are fixed; here they are dynamic.

Image: Dynamic buffers adjustments over time: ForgeFlow DDMRP App — inventory zones adapt based on real demand changes to keep the supply chain balanced and responsive.

4. Demand Driven Planning (Pull)

Generate supply orders only with real, qualified demand signals (confirmed sales orders) within the immediate horizon.

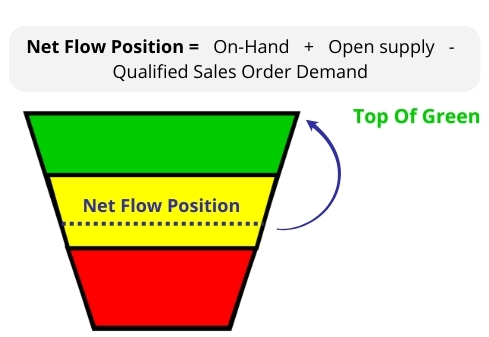

Figure: Net Flow Position calculation and buffer zones — three-color inventory zones.

Figure: Net Flow Position calculation and buffer zones — three-color inventory zones.

- Uses the Net Flow Equation:

On-Hand + Open supply - Qualified Sales Order Demand

- Buffer zones (three-color model):

- Red: risk of stockout

- Yellow: alert zone

- Green: optimal stock

- When the level drops below the yellow zone, an order is automatically generated to bring inventory back to the top of the green zone, ensuring availability while minimizing excess stock.

With this approach, companies achieve continuous flow, fewer stockouts, and lower inventory costs.

5. Visible & Collaborative Execution (Pull)

Manage open supply orders with clear priorities based on buffer position:

- Lower available inventory = higher priority.

- In contrast, MRP prioritizes only by due date.

5. Benefits of DDMRP

- Customer Service: 97-100% On-Time Performance.

- Lead Time Reduction: up to 80%.

- Lower Inventory: typical reductions of 30-45%.

- Reduced Supply Chain related costs.

- Relevant and Reliable Information for Planners.

At ForgeFlow, we have seen firsthand the huge impact that the DDMRP methodology have on our manufacturing and distribution clients.

This transparent, intuitive, and sustainable approach to modern supply chain management effectively mitigates the challenges posed by traditional MRP systems and the growing complexities of today's industrial environments.

Basic Guide to Understanding DDMRP